Benelux

United Kingdom

India

Slovakia

USA

Italy | EN

Contact

Downloads

Benelux

United Kingdom

India

Slovakia

USA

Benelux

United Kingdom

India

Slovakia

USA

Here you will find an overview of our standard and special program.

Do you need a special design? Please get in touch with us.

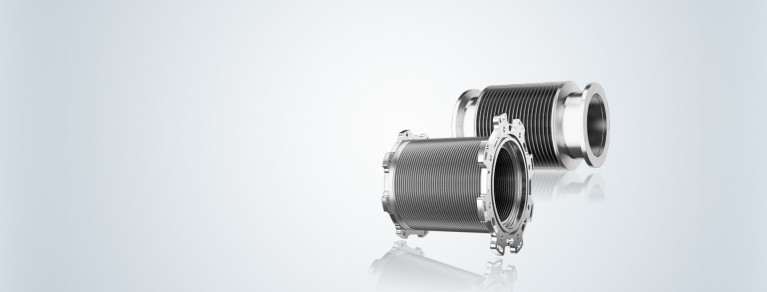

As highly flexible parts, edge welded bellows are used for the absorption of movements, decoupling. lead-through, volume compensation usually in vacuum applications, or for low differential pressures. As a sealing or spring element with defined properties, edge welded bellows are also a functionally relevant component in vacuum valves or floating ring seals. Our broad portfolio of dimensions and materials offers customised solutions for every application, with defined degrees of purity on request. The components can also be used at high temperatures or cryogenic temperatures.

Diameter range: from 6 mm to 300 mm

Materials: Austenitic steels, Ni-based alloys, titanium, and hardenable alloys

There is nothing like direct contact. We will gladly take the time for a personal discussion and answer your questions individually.

Mr. Felix Heel

Project Engineer

E-Mail:

felix.heel [at] witzenmann.com

Tel.: +49 7231-581-4162